Takataka Plastics

Transforming waste, empowering communities

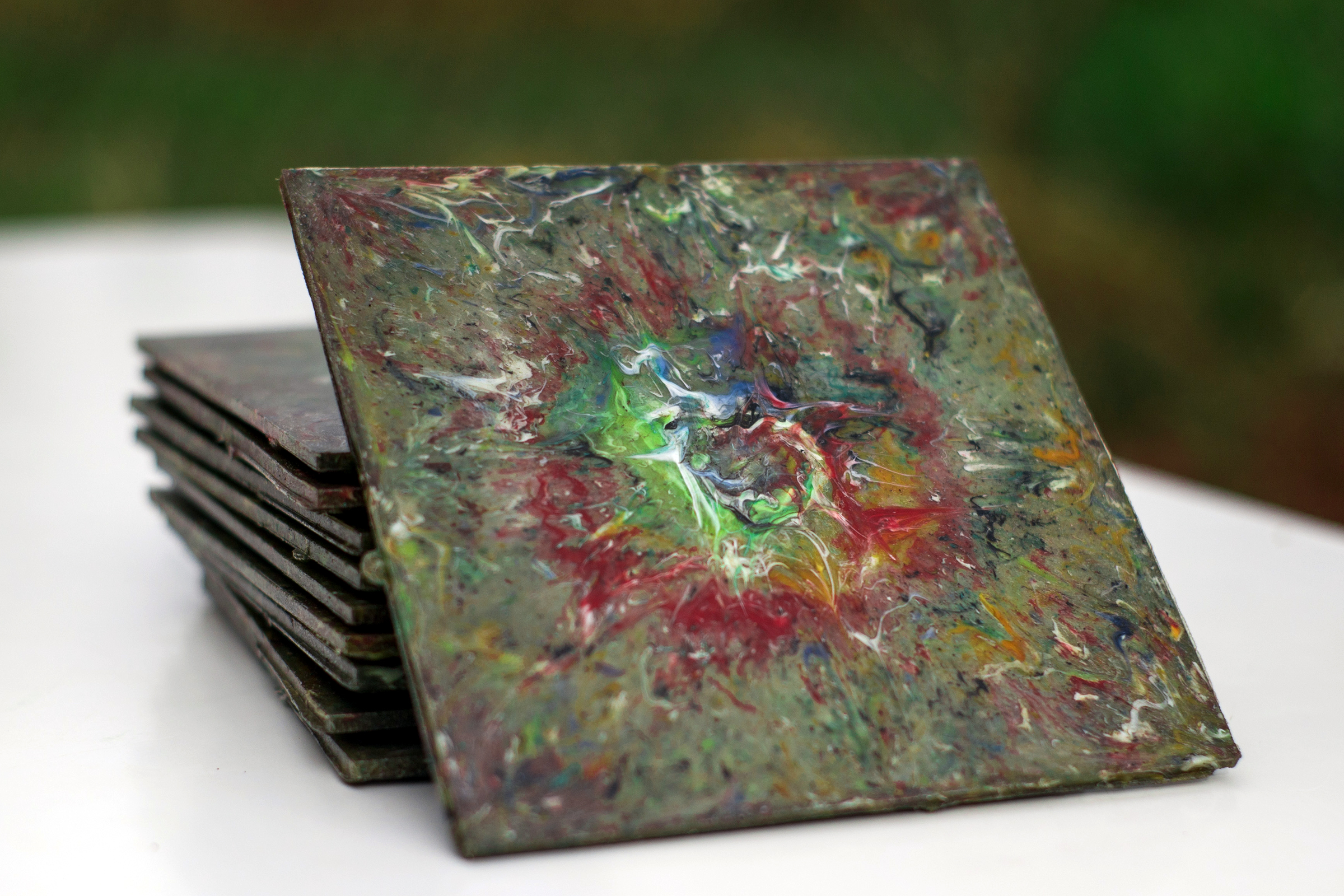

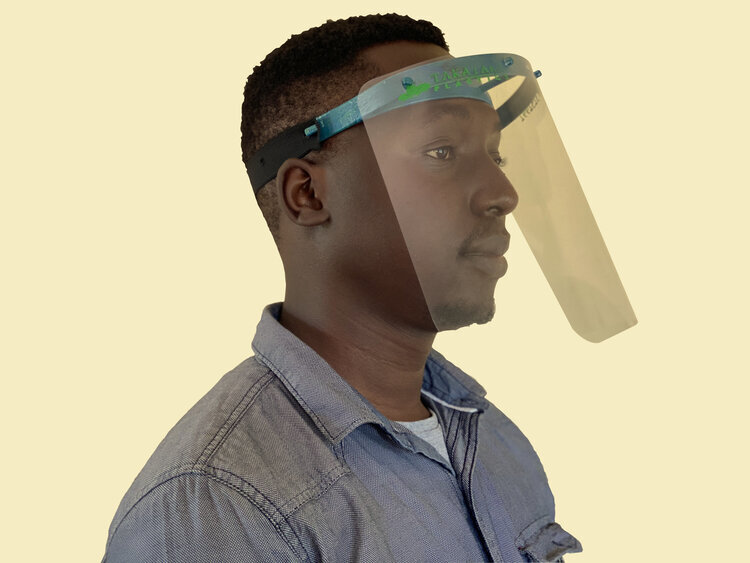

Takataka Plastics collects plastic waste and uses locally produced machines to shred, melt, and mold these materials into saleable products. The enterprise currently produces wall tiles, face shields, and coasters. Locally fabricated, the machines used are cheaper than importing equipment and easily maintained and repaired.

The enterprise designed a small-scale, manually operated machine model which helps create many jobs for unskilled, street-connected youth. This model also enables low-cost scalability.

Eco-Inclusive Impacts

Takataka employs trauma survivors and promotes tangible healing through meaningful work and a supportive workplace community. They reduce environmental and health hazards in places where waste is burned or littered.

- Providing decent job opportunity to youth who live and work on the streets, the group vulnerable to child trafficking and violence

- Providing early intervention, basic life skills, and counselling for those who have experienced trauma, exploitation, and human trafficking

- Providing a recycling service that did not exist

- Reducing environmental and health hazards in places where waste is burned or littered

- Recycled over 1,000 kg of plastic waste in 2020; preventing nearly 20 tonnes of CO2 from entering the atmosphere each month

- Creating income opportunities for marginalised and vulnerable groups

- When at full operation in Gulu, the enterprise estimates a gross profit of $2.17 per square meter of wall tiles produced and an annual gross profit of $33,000

Partners

Takataka Plastics solves the problems of plastic waste and youth unemployment in Uganda by locally recycling plastic waste into quality construction materials and medical equipment and creating jobs for former street youth.

CEED Uganda helps in sensitising members of the community about sustainable waste management. Takataka Plastics also collaborated on an innovation lab for youth in environmental sustainability start-ups.

Takataka Plastics and Gulu University work closely together on research and development of both equipment and products.